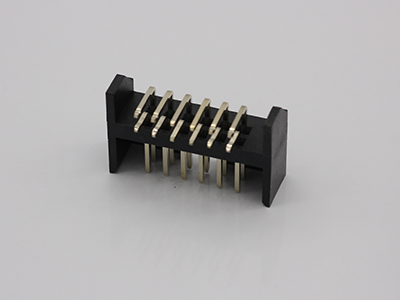

The connector industry is very large, and there are many types, such as IT host internal connectors, host peripheral connectors (I/O), equipment connectors, mobile phone connectors; industrial connectors, automotive connections connectors, new energy connectors, etc.; through the communication with the predecessors of the connector and the collection of relevant market information, I will work with you to understand the basic connectors

Imagine what it would be like if there were no connectors? At this time, the circuits should be permanently connected with continuous conductors. For example, if an electronic device is to be connected to the power supply, both ends of the connecting wire must be firmly connected to the electronic device and the power supply by some method (such as welding); As a result, it brings a lot of inconvenience both for production and use.

Take the car battery as an example. Assuming that the battery cable is fixed and welded to the battery, the car manufacturer will increase the workload for installing the battery, increasing the production time and cost; when the battery is damaged and needs to be replaced, the car must be sent to the repair station. , desoldering to remove the old one, and then soldering the new one, which requires more labor costs; with the connector, you can save a lot of trouble, buy a new battery from the store, disconnect the connector, remove the old battery, install Put a new battery on and reconnect the connector; this simple example illustrates the benefits of the connector; it makes the design and production process easier and more flexible, reducing production and maintenance costs.

The benefits of using connectors: It makes the design and production process more convenient and flexible, reducing production and maintenance costs.